SB Television

A Melges 30 Redo: Deck and Rigging Upgrades

Jon Shampain and Robert Plant’s Melges 30 Still 2 Crazy, rehabbed and racing in San Diego’s Hot Rum Series.

Mark Albertazzi

Jon Shampain and Robert Plant’s Melges 30 Still 2 Crazy, rehabbed and racing in San Diego’s Hot Rum Series.

Mark Albertazzi

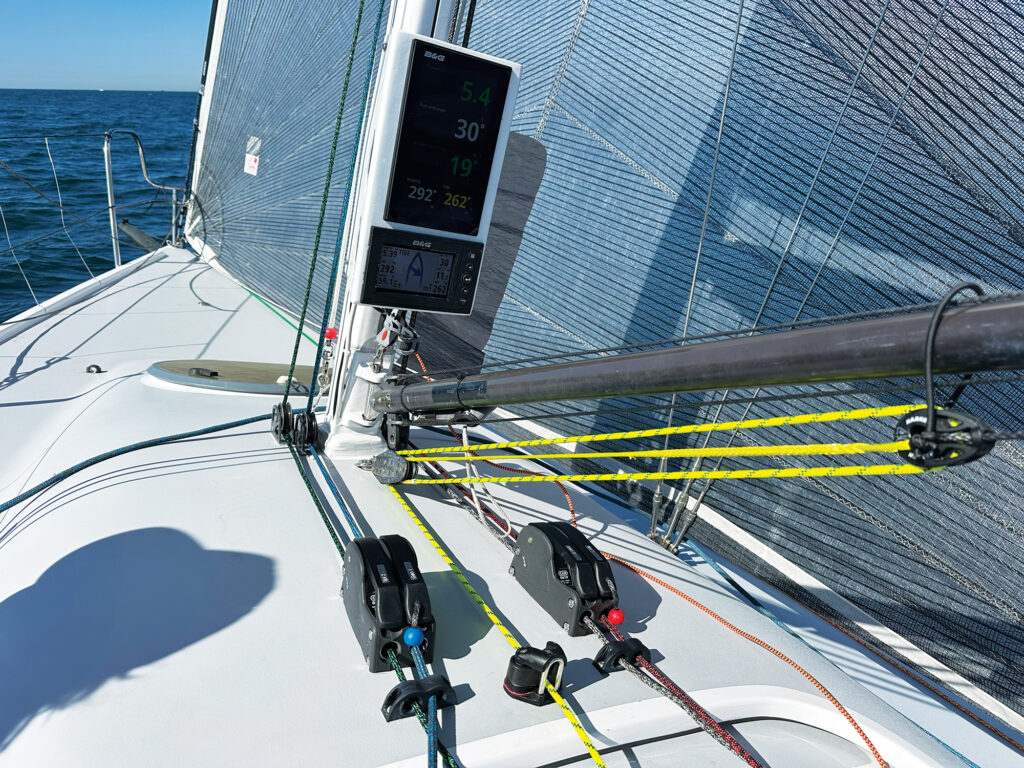

Before we tackle the hardware phase of the Still 2 Crazy project, let’s rewind for a moment to its beginnings. My father, Jon Shampain, and his boat partner, Robert Plant—with my help—purchased and started a full rehab of a vintage 1996 Melges 30, a sportboat that had runners, an articulating bowsprit, and overlapping genoas. Dad and Plant started by stripping the boat completely, even removing the chainplates. Then every hole was filled, and delamination in the gelcoat was ground away, filled, and faired. Because the boat is now almost three decades old, we added knees under the stanchions and ribs under the genoa lead system to prevent the deck from flexing. We also added laminate under areas where we knew there would be high loads, such as under padeyes and runner-block attachments. We added winches for the runners, so we also added pads and backing plates for the new winch locations.

The runners were a good place to start. Originally, the boat had a purchase system that led belowdecks. While it was lightweight, it also was complicated, with many moving parts, and it allowed water to get inside the boat. So we opted for a 2-to-1 above-deck system that leads to a pair of Harken 35.2ST Performa winches, which are powerful yet smaller self-tailing two-speed winches. This should give us good control of the mast when tacking and jibing in a big breeze.

Using Harken’s online resources, I printed and built a scaled-to-size mock-up of the winch and positioned it where we wanted it on the boat, to verify that the line would reach the winch without affecting other systems. Incorporated in the system is a series of the 57 mm Black Magic blocks, which are the perfect size and strength to handle the runner loads on this 30-foot fractionally rigged sportboat. At the top, we have the purpose-built 57 mm runner block, which is designed for runners. At the stern, we have the standard 57 mm Black Magic blocks attached to the boat with Dyneema loops. In the cockpit, the 57 mm Black Magic foot blocks direct the runner to the winches.

The mainsheet system got a makeover as well. The original fine-tune adjustment ran through a purchase belowdecks. And while it was clean, like the runner system, it let water down below. I exchanged that for a standard system, similar to what you’d find on a Melges 32—a 6-to-1 with a cam base behind the traveler and a 4-to-1 fine-tune on a low-profile base in front of the traveler. We use 57 mm soft-attachment Carbo blocks on the boom and a double Carbo block on the traveler car. The fine-tune uses 40 mm Carbo fiddle blocks. For the mainsheet and fine-tune cleats, I spec’d the Harken fast-release fairlead. I find that it is easier to cleat and uncleat, and it has less friction on the big eases. The traveler itself has a 3-to-1 using a combination of 40 mm and 29 mm Harken Carbo blocks.

We had some fun with the genoa car system. The boat was designed with tracks for the genoa and separate tracks for a jib, along with all of the purchase systems needed for the cars. It was all pretty old, and it was looking as if we were going to have to replace all of the tracks and cars. Instead, we designed a floating lead system that is light, cost-effective and simple. Under the location of the genoa and jib hardware, we mounted Harken’s 12 mm bolt-down fairleads to the deck. Then we spliced in a 2-to-1 Dyneema strop to Harken’s floating-jib lead rings. These were spliced to a 3-to-1 purchase led to a cleat near the genoa winch. The strops for the No. 1 genoa and No. 3 jib are spliced together so that one line adjusts everything. Last, we added the Harken Grand Prix jib lead eye in front of the winch to prevent overrides. Voilà! Floating leads that are simple, easy on the pocketbook, and still have the 6-to-1 purchase for easy adjustments. The genoa lead cleats have Harken’s extreme-angle fairleads, which align the rope and allow us to cleat and uncleat them from the weather rail.

While on the genoa system, I was unsure how I wanted to set up the outboard leads. While I try to avoid adding stainless parts to a sportboat because every ounce matters, there is a time and a place for everything, and once again, Harken had something special. In the locations we thought that the outboard leads should go, we mounted 56 mm fixed padeyes (Harken 2759) with two bolts. Folding padeyes are great and Harken’s new Gizmos are great, but I really wanted to get the eyes as far outboard as I could, and that meant fastening them to the curved radius of the deck/hull joint. A two-fastener fixed eye let me mount them inline on the rail on a curved surface. They have a round eye built in and are very strong. I can attach a block to them, I can run a sheet through them, or I can clip a shackle or carabiner to them. And with working loads around 2,500 pounds, weighing just 1.3 ounces each and costing less than $20 apiece, with these I could do no wrong.

I’ve long felt a need for a high-load block similar to the 57 mm Black Magic block but one that was a little smaller. Harken’s new Fly blocks are amazing but too small for what I had in mind. As if to answer my prayers, Harken designed a new 45 mm Black Magic loop block—exactly what I wanted for the aft spinnaker blocks. They easily take the load, run smoothly, and are very light. In front of them are 75 mm Harken Carbo ratchet blocks. In light air, we can trim without a winch; in heavy air, we can turn the ratchets off and trim on the winches.

Another area that got a full makeover was the articulating-bowsprit purchases. There is a pole extender, a pole retractor, a pole-pull to starboard, and a pole-pull to port—each with its own purchase system belowdecks. Originally, they were led through the back of the companionway or the side of the cockpit. These were places where plenty of water could egress. My father came up with the idea to lead it all to cleats inside the companionway but facing outward to where the pit person would naturally be in maneuvers.

A thorough refit of the hull and meticulous upgrades to hardware and running rigging were made.

Mark Albertazzi

A thorough refit of the hull and meticulous upgrades to hardware and running rigging were made.

Mark Albertazzi

But because it wasn’t my idea to begin with it, I didn’t like it. But he got his way, and I admit that it works extremely well. Just inside the companionway are two standard cam cleats angled out to the cockpit with, you guessed it, extreme-angle fairleads on them. It really makes cleating, uncleating, and lining up the rope with the cleat a breeze. The pole-out incorporates a pair of medium-size Harken wire blocks. These are very strong and good when using small, uncovered Dyneema lines.

A 2-to-1 purchase is plenty for this function. As it is with the pole in, we did a 2-to-1 after trying a 1-to-1. There was some binding in the pole system, and the 2-to-1 seemed to alleviate that. Because less strength is needed for this function, we were able to use lighter Harken Carbo blocks. Because the articulation controls load up a fair amount more, we designed an 8-to-1 system using Harken Carbo blocks at the back end and high-load wire blocks at the front.

The boat came with an older code zero, and I was eager to get it on a furler because furling these sails makes setting, dousing, and use in general so much easier. Our previous Still Crazy had a great Harken unit, so I was confident that it was the way to go for us. The Harken Reflex Unit 1 furler with the top-down furling option and Harken’s 10 mm Torsion Cable was an easy choice. I am a fan of the interchangeable bottom pieces, so you can have one lower drum and multiple spinnakers with torsion cables ready to go. Clip in and clip out for easy storage or sail changes. In addition, we installed a retractable bobstay to help us maintain luff tension when sailing with the code zero.

The Lineage ReportAs a part-time rigger, I enjoy finding different ropes and exploring applications for them all. I worked with Marlow on this project. Let’s start with one of my favorite ropes and one of my go-to products for J/70 rigging: Marlow’s D12 MAX cores. This core is available in SK78 and SK99. It is strong and has nearly zero stretch. This is a key ingredient for jib halyards, main halyards, control pennants, backstays and runners. It’s also important in spinnaker halyards and tack lines, especially on boats with code zeros, where maintaining luff tension is essential. We used a lot of it on this project, and it’s performing as expected. Because it’s strong and also easy to splice, we were able to use 6 mm on the primary runner and 3 mm on the checkstays and topmast runners.

For spinnaker and genoa halyards, we chose their MGP Tech 50 covers with the D12 Max core. The MGP Tech cover is a Technora-based cover that is very grippy in the clutches and on the winch while providing good durability and chafe resistance. In fact, it’s so good in the hands and with chafe resistance that we also used it for the genoa sheets. For spinnaker halyards, we chose small Tylaska shackles and added Marlow’s chafe sleeve to reduce chafe when the halyards pull off center at the top. We are trying Tylaska’s spool shackles on the jib halyards. They are working well, albeit I need to lengthen the splices to accommodate the press rings in some of the older sails

For the runner tails on these fractional boats, heat resistance is key because the rope heats up under so much load when eased. For this reason, we went with Marlow’s MGP P Tech 50. While similar to the rope described above, the P tech has PBO woven in to help with the heat resistance. Of course, because overall stretch is a concern, D12 Max is in the core. To keep the weight down, we spliced a lightweight tail into it where it will never be loaded. We used Excel R8 for a clean and finished look that matched the runner tail itself.

For the spinnaker sheets, I wanted an all-purpose set and a light-air set. For the AP set, Marlow suggested the same cover as the genoa sheets and halyards: MGP Tech 50 but with a low-stretch softer core, such as D12 78. It sounded like a great idea and has proved itself well. For the light-air sheets, we went with another recommendation from Marlow: Excel HPR 6.5. It’s lightweight, strong, and easy to grip.

MGP Furler 50 is excellent for the code zero furling lines. It provides good grip in the furling unit and is easy to splice in a continuous loop. We added a small detachable block on a bungee with a clip so that the unloaded end stays tensioned. This keeps the continuous furling drum from back-spinning as you furl.

Tack lines live in clutches and are not adjusted much, so we thought we could use a simple cover over the D12 Max. MGP Racing fit the bill, with a simple polyester cover that is cost-effective but still works well in the hands and clutches.

We used plenty of Excel Racing for control lines as well. It is a Dyneema-cored polyester-covered line that’s great for jib leads, vang, cunningham, outhaul, traveler, etc. It comes in many sizes and colors.

The post A Melges 30 Redo: Deck and Rigging Upgrades appeared first on Sailing World.

- Home

- About Us

- Write For Us / Submit Content

- Advertising And Affiliates

- Feeds And Syndication

- Contact Us

- Login

- Privacy

All Rights Reserved. Copyright 2025, Central Coast Communications, Inc.